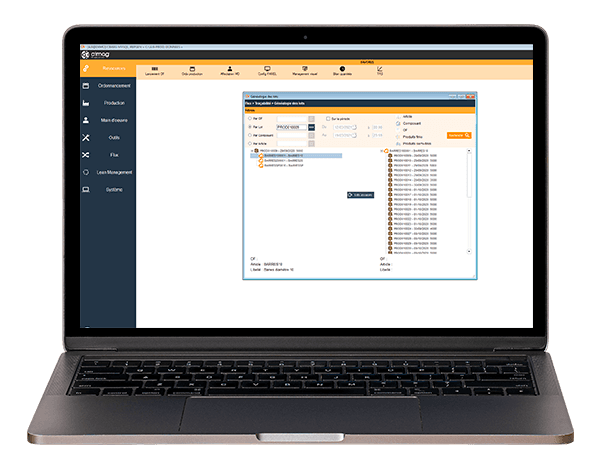

Traceability and genealogy

Accurately record, track and trace all products, components, and equipment in your plant.

The Cimag Production – Traceability feature enables you to use a barcode label to identify and track each product, component, sub-component, equipment and transfer that have previously been recorded in the database through stationary or portable terminals. The labels are generated at the ERP or CIMAG level.

Traceability Software Features:

- Raw materials and components: batch management, consumption input, batches produced

- Tracking components and WIP inventory by barcodes or RFID

- Tracking production equipment and tools

- Traceability of each operation sequence

- Automatic timestamping of each stage of the production process

- Printing of barcode labels and coding of RFID tags

- Batch genealogy: upstream and downstream batch traceability

Benefits of Traceability:

- Produce in accordance with bill of materials

- Ensure product conformity

- Record and track the use of each batch

- Monitor process settings

- Comply with regulations and customers’ requirements

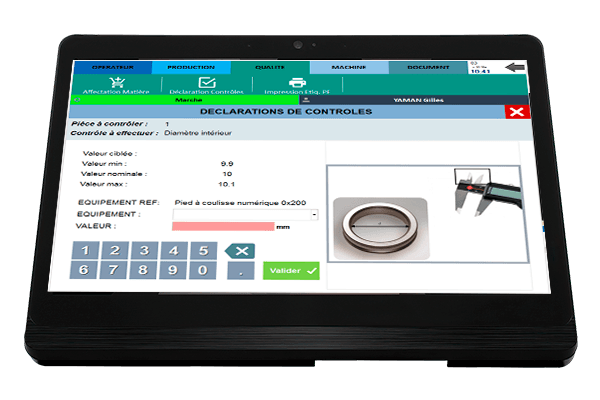

Process Management Features:

- Dynamic display of electronic work instructions/SOPs

- Sequencing of the production process (operation routing, bill of materials, etc.)

- Monitoring of procedures

- Identification of machine status and quantities produced

- Set up and trigger alerts in the event of disregard for or deviations from the production process

- Digital up-to-date versions of procedures and work instructions

Benefits of Process Management:

- Edit and approve production sequences

- Access a comprehensive timeline and history of procedures

- Identify recurrent labor errors

- Set up operation sequencing/routing in a compelling and flexible way

- Profit from a comprehensive overview of WO progress in real time

Production flow

Stay informed of your inventory status and track production progress in real time.

Product Flow Software Features:

- Identification of the raw materials and components used in each step of the production process

- Access to an accurate overview of product availability in real time

- Monitoring the location and status of each product

- Management of supply lists by WO/production chain/ location

- FP (Finished Products) identification according to various standards: RFID EPC, GS1 barcodes, GALIA barcodes, etc.

Benefits of Product Flow Management:

- Enhance the reliability of the data regarding your inventory

- Further improve the efficiency of your supply chain

- Know the consumption of raw materials by location and WO

- Monitor the flow of WIP inventory and finished products

- Provide controlled finished products to logistics