Data acquisition to monitor industrial production

Retrieve your shop floor data in real time.

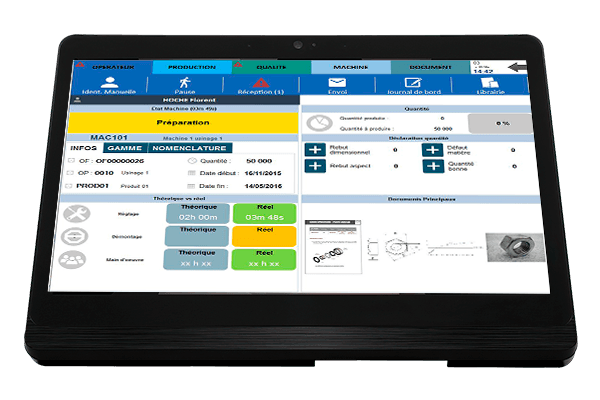

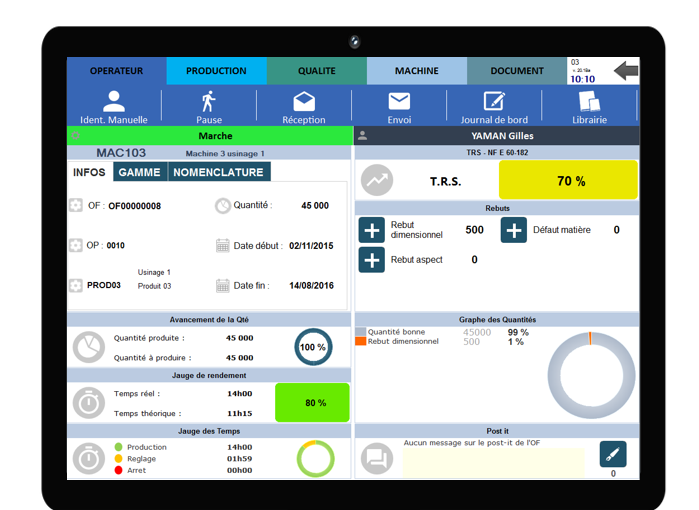

With the Cimag Production software – Data Acquisition feature, you can easily and effectively collect machine times, causes of machine downtimes, and labor times by using different techniques and hardware. Regardless of the hardware, communication with the server is achieved on the company’s Ethernet, by wire connection or by radio waves connection such as WIFI.

Through this function, you can not only ensure OEE (Overall Equipment Effectiveness) monitoring in real time, assessed using reliable data, but also focus on relevant actions leading to continuous improvements.

Production Monitoring Software Features:

- Automated and real-time data extraction

- Retrieve machine information (direct connection to terminals)

- Monitoring of machine status (production, setup, cleaning, downtimes, breakdowns, etc.)

- Monitoring cycle times, finished products, and scraps

- Possibility to set up a direct connection to Programmable Logic Controllers (PLCs) or by Open Platform Communications (OPC)

- Management of local devices directly from workstations

- Management of raw materials and components by barcodes or RFID

Benefits of Production Monitoring:

- Easily collect machine times, root causes of downtimes and production counters

- Ensure the reliability of information in your workshop

- Reduce time spent entering production data in the ERP

- Collect mixed data from PLCs, scales, production counters, etc.

- Monitor productivity and production process parameters

Labor Management Software Features

- Operator badge identification

- Calculation of workforce performances

- Analysis of labor occupancy times

- Monitoring of productive and non-productive times

- Manage skills and capacities

- Creation of an assessment of labor utilization

- Estimation of the impact of physically demanding jobs

- Easily integrated with the time and attendance management module

Benefits of Labor Management

- Easily retrieve labor times

- Assign the right resources to the right jobs

- Organize work teams according to constraints (absences, teams’ turnover, etc.)

- Knowing operators’ occupancy times

- Manage capacities and skills

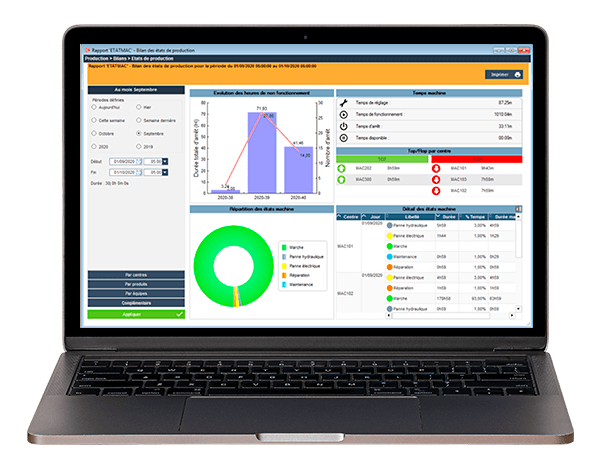

Monitoring Software Features

- Monitor the OEE, OOE and efficiency indicators

- Time track machines and workforce

- Time analysis, WO reporting, and operators’ appraisal

- Instant performance reporting

- Manufacturing Business Intelligence

- Dynamic dashboards

Benefits of Analysis

- Provides an overview of the status of the shop floor

- Manage one or several workshops in real time

- Implement visual management

- Make the right decisions at the right time

- Monitor production progress

Shall we talk?

Alpha-3i has over 25 years’ experience in implementing MES software. Today, over 400 industrial sites use our solutions.

We know your industry, your issues and your challenges, so you can rely on our expertise to implement modular, customizable MES software integrated with your information system.