Collect production floor data and make it usable in real time on your factory

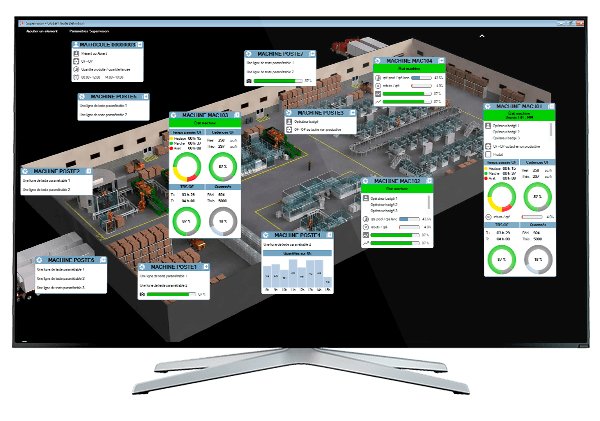

Cimag Production’s visual management function provides a real-time overview of the workshop through production monitoring.

Screens can be set up on the shop floor, at the end of the line, by cell or in the meeting room, to display production data and improve team communication. The set of indicators to be displayed is easily defined by the workshop manager, using a list of widgets (OEE, machine status, rates, quantities, etc.). Thanks to this instantaneous display, teams can react quickly to any unforeseen events.

Supervision is an essential element of workshop management, as it enables regular reviews with operators, based on reliable data.

Want to view production progress in real time?

Visual Management Software Features:

- Retrieve machine information in real time by direct connection to PLC

- Traceability and supervision of machine parameters

- Communicate with most PLCson the market through dedicated gateways or using OPC

- Visualize performance in real time

- Connection to other equipment (scales, cells, etc.)

- ANDON system: instant visibility of production problems for immediate action

Benefits of a visual management tool:

- Alert teams in real time to events in the plant

- Easily collect machine data, downtime causes, counters, etc.

- Monitor machine parameters in real time

- Lead team meetings and share data

- Optimize productivity

Should we talk?

Alpha-3i has over 25 years’ experience in implementing MES software. Today, over 400 industrial sites use our solutions.

We know your industry, your issues and your challenges, so you can rely on our expertise to implement modular, customizable MES software integrated with your information system.