Want to monitor your production in real time?

Data acquisition for industrial production monitoring

Collect data from your workshop in real time.

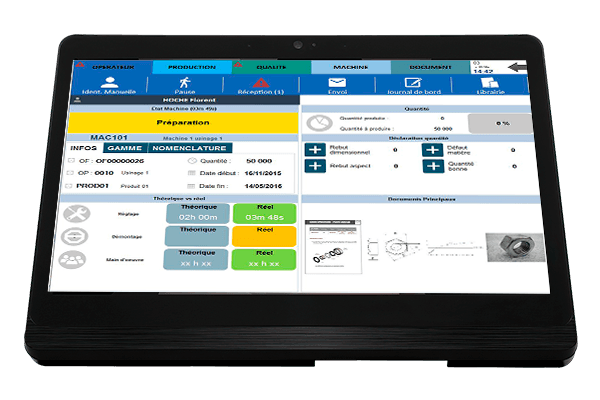

The data acquisition feature of Cimag’s real-time production monitoring software enables machine monitoring and easy collection of production times, downtimes, causes of downtime, production quantities and labor times, using different technologies and hardware.

Regardless of the hardware selected, dialogue with the server takes place over the company’s Ethernet network, using either a wired or wireless connection.

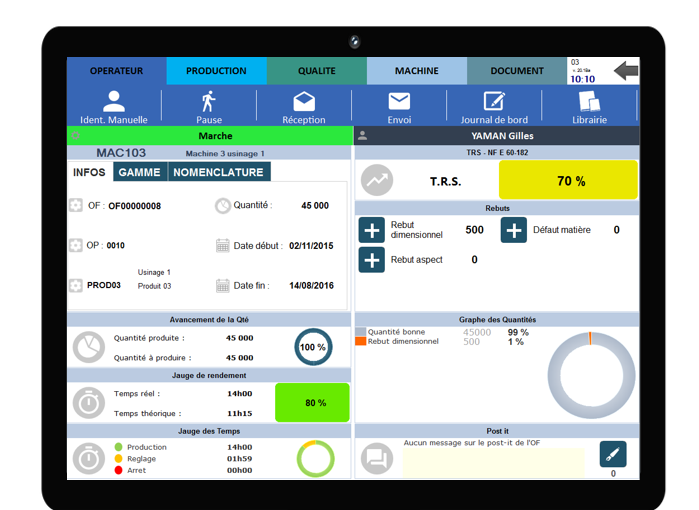

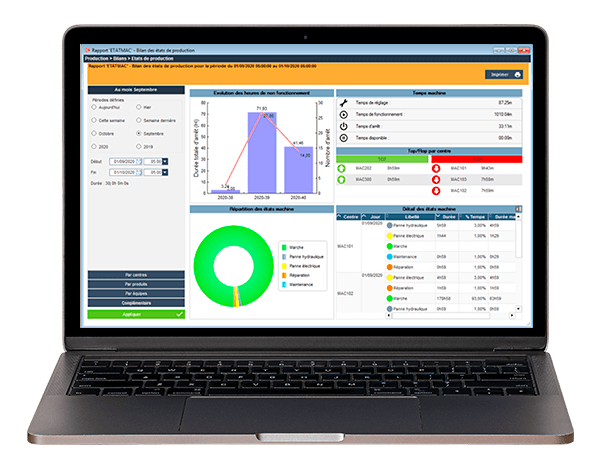

The data acquisition feature ensures real-time OEE monitoring, calculated from accurate data collected as close as possible to the workshop. Access to all this production data makes it possible to implement a continuous improvement approach.

Production Management Software Features:

-

Perform automated, real-time data acquisition for machine monitoring

-

Collect machine data ( connected directly to the terminal)

-

Record status times (production, settings, cleaning, breakdowns, etc.)

-

Track rates, finished products and rejects

-

Enable direct connection to PLCs or through OPC

-

Manage local devices directly from the workshop terminal

-

Manage components using barcodes or RFID

Benefits of Production Management software:

-

Easily collect machine times, downtime causes and production output counters

-

Make workshop information more reliable

-

Reduce time spent re-entering production information into the ERP system

-

Collect heterogeneous information from PLCs, scales, counters, etc.

-

Monitor productivity and process parameters

Workforce Management Software Features

-

Operator badging

-

Calculate workforce performance

-

Monitor productive and non-productive time…

-

Analyze occupancy times

-

Integrates with our time management module

-

Create a workforce assessment report

-

Help to calculate workload

Benefits of Workforce Management

-

Easily collect workforce times

-

Assign the right resources to the right workstations

-

Organize work teams according to constraints (absences, shift rotas, etc.)

-

Monitor operator occupation times

-

Manage skills and competencies

-

Performance analysis

Production monitoring Software Features

-

Monitor OEE, OOE, TEEP, efficiency indicators…

-

Monitor machine and workforce times

-

Perform time analysis, WO reporting, operator assessment

-

Instant performance reporting

-

Manufacturing Business Intelligence

-

Dynamic dashboards

Benefits of performance analysis

-

Gain visibility of the workshop situation

-

Supervise one or more workshops in real time

-

Implement visual management

-

Make the right decisions at the right time

-

Monitor production progress

Should we talk?

Alpha-3i has over 25 years’ experience in implementing MES software. Today, over 400 industrial sites use our solutions.

We know your industry, your issues and your challenges, so you can rely on our expertise to implement modular, customizable MES software integrated with your information system.